marinaflexx® parquet flooring, waterproof, ship's floor

Specifications:

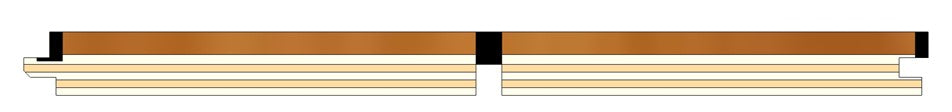

Type: Plank (2-strip)/ marinaflexx®

Warranty: 5 years

Wood type: Oak

Sorting: A natural growth in combination with natural color differences and small, visible branches.

Surface: sanded, oxidatively oiled

Chamfer: none, PU sealing joint

Format: 1790x135x10mm

Wear layer approx.3.5mm

Packaging Unit: 2.4165m² (1 packaging unit of 10 planks corresponds to 2.417m²)

Construction: waterproof glued plywood

Laying:

Sonnberg Marinaflexx must be glued over the entire surface using a plasticizer-free adhesive and additionally glued on all sides using a waterproof glue in tongue and groove. Only by following these installation instructions can a seamless wooden floor be created.

Underfloor heating:

Guidelines for the installation of wooden floors on hot water underfloor heating and screeds in accordance with Ö-Norm B 5236

General

A coordination meeting must be held between all contractors involved. We ask you to inform us of the date for this coordination meeting, only if the floor is installed by Puchegger and Jilg. GesmbH. If there is no date for a coordination meeting, we have fulfilled our obligation to inform you. Wood has a suitable thermal resistance and even heat distribution, so it is recommended for installation on underfloor heating. According to Ö-Norm 5236, glued parquet up to a thickness of 24 mm is permitted for underfloor heating. Wood floors must be fully glued on almost all classic hot water underfloor heating systems.

Preparation

According to Ö-Norm, a screed with underfloor heating must be heated. The temperature is increased gradually, a flow temperature of 45° is maintained for a longer period and then lowered again. The screed must be heated until it is sufficiently dry. This heating process must be recorded and forwarded to us. If we do not receive a heating protocol, the parquet cannot be laid. If the agreed laying date is postponed, this can result in longer waiting times. The moisture content of the screed must not exceed 60 HM% at the time of laying. The screed is measured using the HM Box; the underfloor heating must be switched off at the time of the moisture measurement.

laying

Basically, the parquet must be glued down when laying on screed with underfloor heating. When laying the floor covering, the surface temperature of the screed must be at least +15°C and must not exceed 20°C when the underfloor heating is switched on. Floating installation is not recommended due to the higher thermal resistance (insulating underlay plus possible air cushioning) and the risk of a tear-off joint, and is also not permitted according to the Ö-Norm.

Parquet sensor (intelligent parquet floor)

Our intelligent parquet floors are equipped with sensors that help you achieve a healthy indoor climate. These sensors are integrated into the underside of the parquet and measure temperature and humidity. You can synchronize the data daily using a free app on a smartphone or tablet.

Your benefits:

- Healthy indoor climate

- Increasing the lifespan of your parquet floor

- Optimizing heating costs

- Information about smartphone and tablet

The underfloor heating in operation

A notice:

Wood is a natural product. Differences in color and structure are characteristics of the natural product wood. Deviations from the pictures and/or samples are therefore unavoidable and do not constitute a complaint.

Product information:

YOUR WATERPROOF WOODEN FLOOR IN BOAT DECK LOOK

marinaflexx® is a unique floor system. Thanks to its seamless processing and oiled surface, it is waterproof and therefore also suitable for wet and damp rooms.

The seamless processing is made possible by the flexx joint. This has been used in shipbuilding for a long time and allows a flexible wooden floor to be created.

When it comes to wood, we only use Sonnberg parquet, which comes from sustainable forestry and is 100% made in Austria.

The interplay of wood and the flexx joint creates the unique look of the floor, which is reminiscent of a boat deck and now enables the warmth and texture of a parquet floor everywhere in residential and commercial use.

Parquet in bathroom & toilet

Especially in barefoot areas such as the bathroom, you want a floor covering that conveys a warm, natural feeling and thus creates a perfect basis for your own feel-good zone.

With marinaflexx® this is now possible – treat yourself to parquet in the bathroom that you can enjoy barefoot without regrets – marinaflexx® is slip-resistant.

Even in the bathroom you can feel like you are on your own boat. The waterproof floor covering now allows real wood parquet to be used in toilets. The seamless installation technique means cleaning is no problem and makes the floor hygienic. Don't worry about stains, they can be removed quickly without leaving any residue in any cracks or joints.

Get a floor in your bathroom & toilet that is waterproof, warm and natural and shines with a unique look as if you were on your own boat.

Water resistant

marinaflexx® was specially developed for the sanitary and wellness sector and is perfect for wet rooms with a waterproof rubber joint, the flexx joint. With prefabricated element construction and the elimination of subsequent jointing work, marinaflexx® is extremely flexible and cost-saving. In combination with underfloor heating, you can create feel-good zones with the highest level of comfort. The marinaflexx® system is a patented floor covering system that creates a waterproof and joint-free real wood parquet floor. The robust prefabricated parquet floor is waterproof, flexible and joint-free thanks to the permanently elastic flexx joint. It is not only resilient and practical, but also catches the eye with its special design.

Made from sustainable materials

All Sonnberg floors consist of a multi-layer structure made of softwood and a precious wood layer, exclusively from sustainable forestry (no tropical wood). Real wood floors are an experience for the senses, they contribute significantly to the appearance of a room and offer the ideal basis for a healthy indoor climate. See, feel and smell your Sonnberg parquet floor every day and ensure your well-being at home. marinaflexx® is made of Sonnberg parquet and therefore relies on sustainable, high-quality real wood, which is 100% produced in Austria.

Produced in Austria

The marinaflexx® planks are made from Sonnberg parquet, which only uses real wood from sustainable forestry. Sonnberg parquet is 100% made in Austria. Out of love for parquet, the Sonnberg Parquet brand was created in 2000 with a small but fine selection of parquet floors. The range now offers a large selection of high-quality country house planks. There is something for every taste and the right parquet floor for every room.

Easy DIY installation

marinaflexx® is a prefinished parquet. This means that the floor is ready to be laid and can be walked on immediately. The gluing is waterproof and the floor is fully glued to the subfloor. Thanks to the patented manufacturing process, marinaflexx is the only wooden floor that is and remains seamless. When laid, the marinaflexx elements are glued together with waterproof glue. The swelling and shrinking of the wood is absorbed by the middle flexx joint, preventing moisture from penetrating. This means that you will have a waterproof and seamless parquet floor in your rooms for the long term.

marinaflexx® System

The robust marinaflexx® multi-layer prefinished parquet elements consist of a wear layer approximately 3.5 mm thick. The approximately 10 mm thick elements are provided with a tongue and groove all around, as well as with the permanently elastic flexx joint and offer optimal protection against the penetration of moisture and humidity.

Cleaning & Care

The seamless parquet is easy to clean and maintain.

The oiled surface and the flexible expansion joint (flexx joint) make the floor hygienic and easy to clean. The jointless installation means less cleaning effort compared to floor coverings with joints, such as tiled floors.

After installation, oiled real wood floors only need to be treated once with PJ oil care, after which the normal cleaning and care process can be continued. You can find more information in the care instructions.